The specified temperatures are the minimum and maximum permissible values in accordance with the declaration in the “Statement of conformity” issued by TÜV Italia srl. For temperatures < -10°C you must use suitable materials.

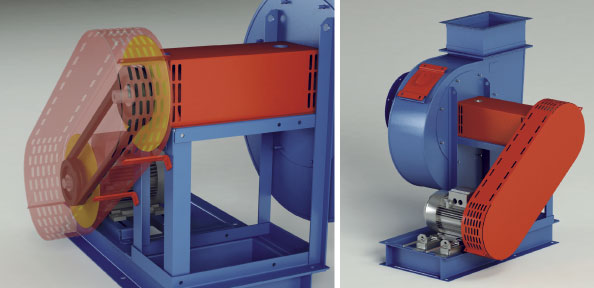

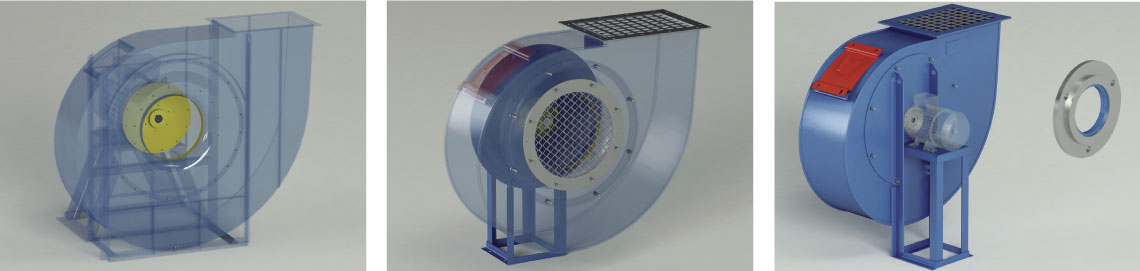

Directly coupled fans, executions 4 and 5

TEMPERATURE CLASS |

AMBIENT TEMPERATURE |

WORKING TEMPERATURE |

|---|---|---|

T135°C (T4) |

-20 ÷ +40°C |

-20 ÷ +40°C |

T200°C (T3) |

-20 ÷ +40°C |

-20 ÷ +105°C * |

T300°C (T2) |

-20 ÷ +40°C |

-20 ÷ +150°C * |

Transmission fans, executions 1, 8, 9, 12

TEMPERATURE CLASS |

AMBIENT TEMPERATURE |

WORKING TEMPERATURE |

|---|---|---|

T200°C (T3) |

-20 ÷ +40°C |

-20 ÷ +55°C |

T300°C (T2) |

-20 ÷ +40°C |

-20 ÷ +135°C |

The following characteristics are mandatory:

*) The ATEX directive and the CE mark impose compliance with the machinery directive, so, in normative terms, the Atex fan must be considered as a partly completed machinery and therefore completely protected. Normally the fan is not a stand-alone system but rather a partly completed machine that is designed for incorporation in more complex systems. Once a thorough risk analysis has been carried out, if safety is guaranteed by the systems themselves, the user is allowed only to remove any guards that are surplus to requirements. Said guards must anyway be kept on hand so that they are available for installation if the fan undergoes a change in its intended use.

In addition to the above points, transmission fans must have: antistatic and flame-retardant belts, guards with brasslinings, suitable versions of interior cases.

The same prescriptions already provided for the 3GD are applicable, and, in addition, the casing must always be welded and the motor must be suitable in relation to the various operating environments. Transmission fans can be certified individually (execution 1) or as “assemblies of components” (executions 8, 9, and 12).